Shaft Mounted Gearboxes

Table of Contents

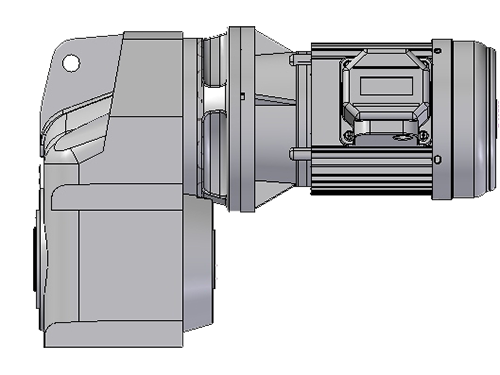

Radicon Series F

Up to – 110kW / 16,500 Nm

more info...

The series F geared motor is primarily designed as a shaft mounted unit incorporating an integral torque reaction bracket. The units are also available with rubber torque bushes, output flanges, output shafts and KIBO sleeves to allow for trouble free maintenance.

All variants can be fitted with IEC motors of your preference or with our standard own brand motor. Input shaft assemblies are available up to and including F10.

The Range Includes

Ten sizes of units F02, F03, F04, F05 F06, F07, F08, F09, F10, F11 and F12.

Version T – Standard unit with torque bush

Version W – Standard unit without torque bush

Version F – Standard unit with output flange

Unit type M – Motorised

Unit type G – Unit to allow fitting of a standard IEC motor

Unit type A – Unit to allow fitting of NEMA motor

Unit type R – Reducer

Unit type S – Reducer unit fitted with a fan

Unit type X – Reducer unit fitted with a backstop

Unit type Y – Reducer unit with a fan & backstop

Design Features Include

Patented standard motor connection (IEC or NEMA).

Ability to fit double oil seals on output shaft as required.

All units are dimensionally interchangeable with other major European manufacturers.

Brake geared motors are available as standard.

Units are manufactured and assembled from a family of modular kits for distributor friendliness maximising availability and flexibility.

Motorised units can be fitted with a backstop module and reducer units can be fitted with a backstop and fan.

As improvements in design are being made continually this specification is not to be regarded as binding in detail and drawings and capacities are subject to alteration without notice.

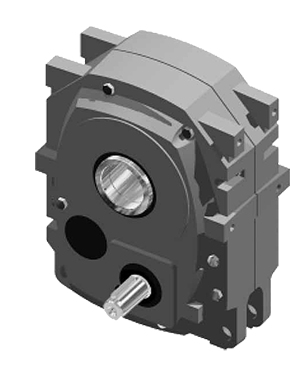

Radicon Series J

Up to – 600kW / 57,000 Nm

more info...

- Worldwide after sales service

- 19 types up to 600 kW, 57000 Nm

- Wide range of standard accessories

- High efficiency

- Long gear and bearing lifetime

- All mounting positions possible

- Easy to mount

- Easy to change speed through change of V-belt transmission

- Space saving

- Low noise level

- Easy to service, due to standard components

The shaft sleeve is supplied with tapped holes for dismounting the reducer as well as locking the reducer to the shaft.*

The input shaft diameter corresponds to IEC standard for motor shafts, thus simplifying standardization of V-belt pulleys and couplings. Locating shoulder provided for pulleys and couplings.

The input shaft is supplied with tapped hole for fitting V-belt pulley or locking washer for V-belt pulley.

All housing contact surfaces are fine milled thus eliminating the necessity for gaskets and possible oil leaks.

KIBO® – One of the most cost efficient dismounting methods that is available on the market, patented by us is available as a standard accessory to every Series J shaft mounted speed reducer.

Modern heat treatment of high quality gives gear wheel and pinions the hard wearing surface and tough core necessary to handle harsh duties.

Manufacturing tolerances comply to DIN and AGMA specifications. Helix angle and small modules give more teeth in mesh for smooth and quiet running.

High quality bearings selected for long service life.

Backstop options are available for all double reduction units (For single stage units on special request).

High quality close grained cast iron housing with maximum rigidity and low weight saves space.

Torque arm bracket will stand up to tough reversible shock load applications allowing for two torque arms to be mounted in opposite directions.

* Not standard for the smallest sizes of single and double reducers.

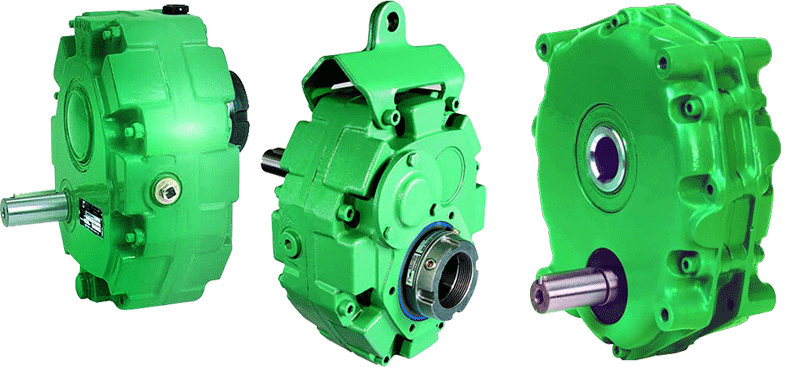

Leroy Somer Poulibloc

more info...

Available in 8 sizes up to 55 kW

4 standard reduction ratios

1/5 – 1/12 – 1/20 – 1/25

Poulibloc 3000

Single reduction gearbox

Reduction ratio 1/5 and 1/8

Cylindrical bore.

Economical series.

Available in 3 sizes up to 11 kW, with oil or grease lubrication.

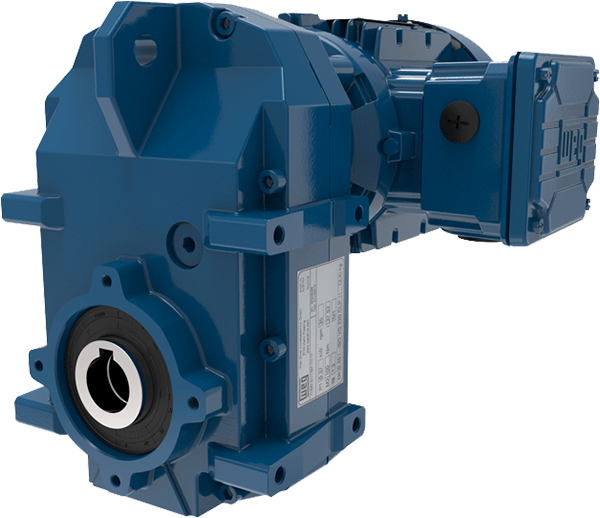

WEG Parallel Shaft Helical Geared Motor Unit